How Dry is Home Depot Kiln Dried Lumber?

Everyone knows box store kiln dried (KD) lumber is for framing houses, not making furniture. So why does it matter what the moisture content (MC) of a stack of 2x4s is? Does it really matter when framing a house if the MC of the studs is 10% or 25%? No, probably not. Partially green studs won’t affect your house in the slightest. However, many of us got started woodworking with the only wood we could afford, box store studs.

I’m not here to judge you for trying to make that end table or even dining table out of a stack of 2x4s or 2x6s. I’m here to help you do it best. The most important thing you can do to give yourself the greatest chance of success is to start your project with wood completely dried to your climate.

I’m going to give a lot information that is pretty interesting to wood geeks. However it really isn’t that necessary to the casual DIYer that just wants to know how to make a quick project out of 2x4s. For those of you that just want the down and dirty numbers and what to do with that information, I’ll save you a lot of reading and give it to you here. For those of you who want to learn how I got these numbers and a lot of interesting wood facts, keep on reading.

Down and Dirty Results for the non-wood geeks:

Lowes and Home Depot don’t grow trees or own sawmills. Their wood suppliers often overlap

Overall average moisture content for my tests: 14.3%

Many boards over 30% MC

Variation of 10-20% MC from board to board in most locations

Truly “dry” lumber should have been around 9%

What this means for those of you who want to build out of KD studs is that wood right off the racks at Home Depot most likely is not a good candidate for furniture. Your best bet is to get a moisture meter to test your wood prior to use. If you don’t want to spend the money on a moisture meter, the next best thing is to purchase your wood and let it air dry inside for 4-8 weeks if possible. That should get it very close to equilibrium moisture content (EMC).

That is an oversimplification of my findings. Read on to see how I got to these results.

Box Store Kiln Dried Lumber Basics

Home Depot, Lowes, Ace, and pretty much anywhere else that sells stud lumber do not grow their own trees. Or even have their own sawmill. They purchase their lumber from one of a handful of timber companies. On the west coast most timber suppliers belong to the Western Wood Products Association (WWPA). The WWPA sets guidelines for all the lumber that comes out of these sawmills so their clients like Lowes can trust they are getting what they paid for.

I’d never really thought about what all those stamps mean on the lumber. Turns out there is a lot of information in there. The information below is directly off the WWPA website. Feel free to check them out for more info: https://www.wwpa.org/western-lumber/interpreting-grade-stamps

You can see some of the types of stamps you will see on lumber supplied by the WWPA. The one I found most interesting was the species stamp. I asked multiple box store employees and not a single one could tell me definitively what species the wood was. Since it was labeled “whitewood” many insisted that was the species. Despite me trying to tell them that Whitewood is not a tree that exists. Eventually after a two minute phone call with Stimpson lumber they were able to answer my question by telling me about the “D FIR” stamp about a third of the way up. Douglas Fir (D FIR) is the common one in Oregon. Hemlock (HEM) was also in some Lowes.

The WWPA gives some guidelines for what KD lumber actually means. You can see in the image from their website there is more than just “KD”. The only KD stamp I saw at any store I sampled was S-DRY, KD. Which you can see should be a maximum MC of 19%. If you keep reading you will see in my tests the average was generally under 19%. But a substantial number of boards were over that 19% “maximum”.

What is important to take from these numbers is that timber suppliers never try and imply they are selling truly dry lumber. Only that it has been partially dried in a kiln. Certainly dry enough for house framing, not dry enough for furniture.

My Test

I decided to actually check the MC of Home Depot and Lowes 2x4s and 2x6s at variety of locations throughout Oregon. In total I sampled four different Home Depot and three different Lowes locations. At each location I sampled ten 2x4s and ten 2x6s. On each board I took a MC reading every 12”. Avoiding rough patches and knots. The rough patches and knots would give inaccurate readings with my moisture meter.

My Tools

To get accurate MC readings you need an accurate moisture meter. The meter I used for this test was the new Wagner Orion 950. Which is the best moisture meter available until you get into large commercial scale meters. It is worth mentioning that the commercial moisture meters are also generally made by Wagner. Wagner is the industry standard for moisture meters. Not just for lumber, but concrete and flooring as well.

Using the Wagner Meters Orion 950

The 950 has two modes, 1/4” and 3/4”. It gets its readings by sending frequencies down into the wood. Unlike a traditional pin meter. Which will only give you a reading for the outer 1/16”. In order to get an accurate reading you need a gap behind the wood you are sampling. If you watch my video on this topic, you will see I elevated my studs by stacking them on two perpendicular studs.

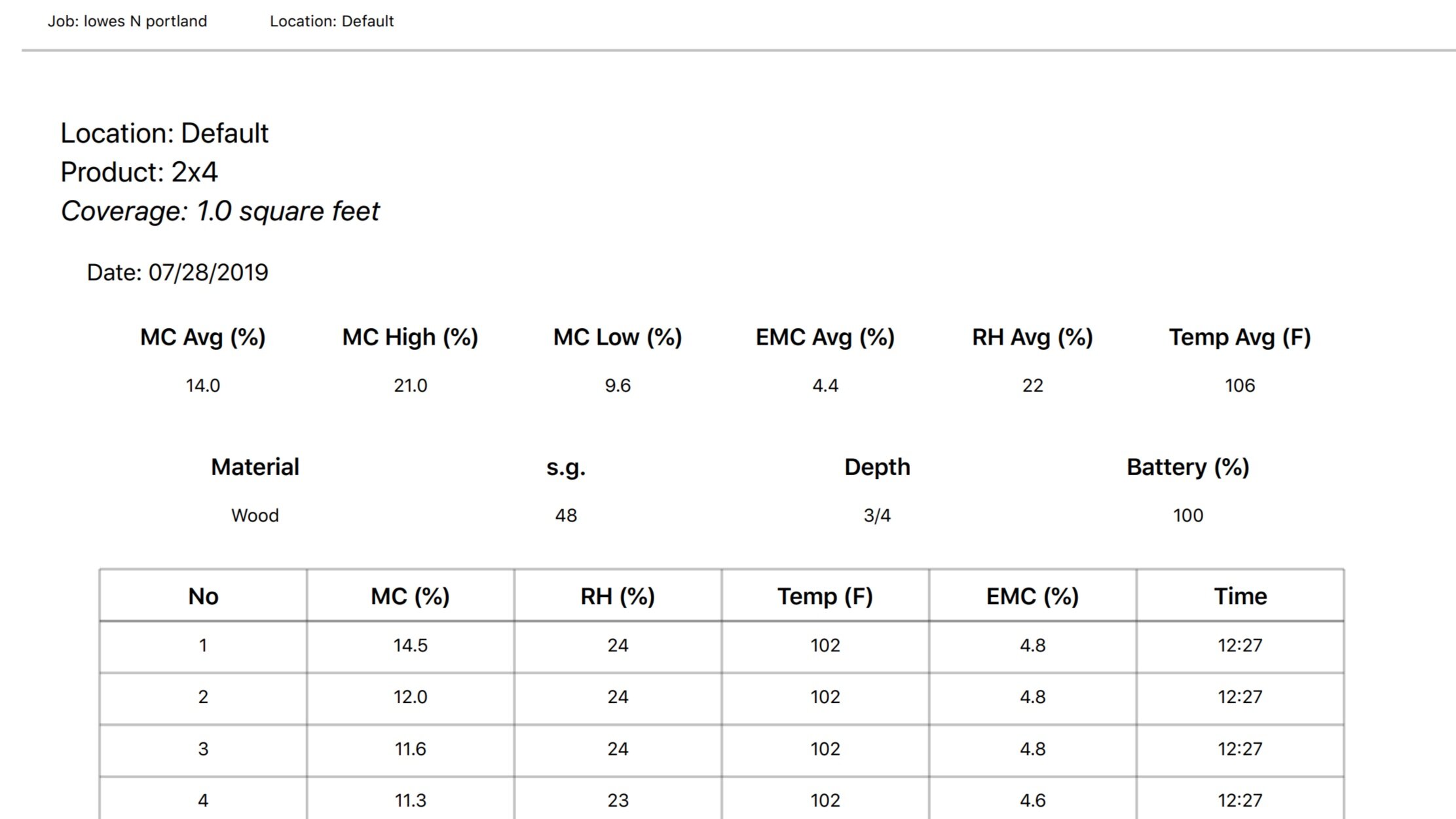

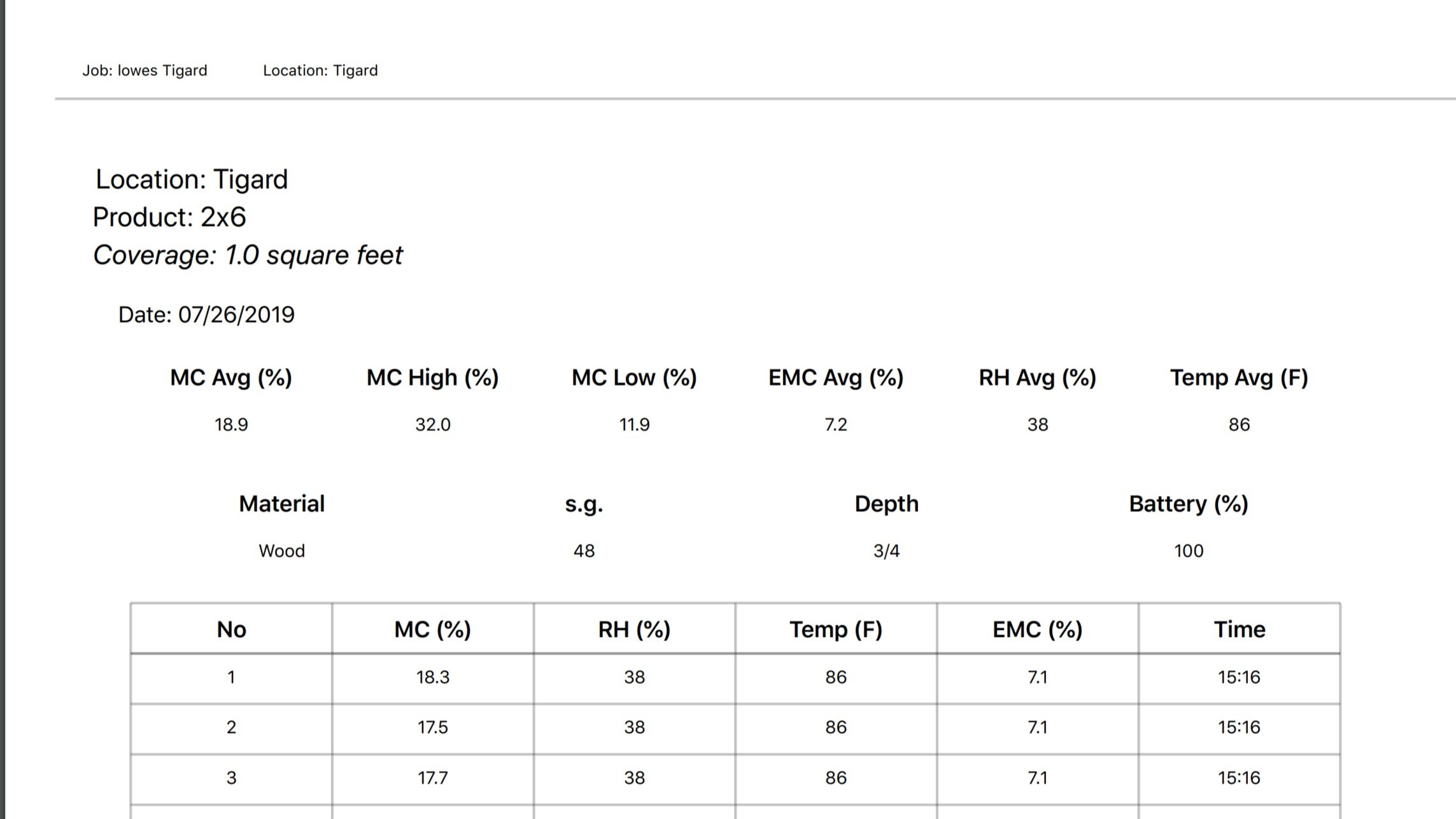

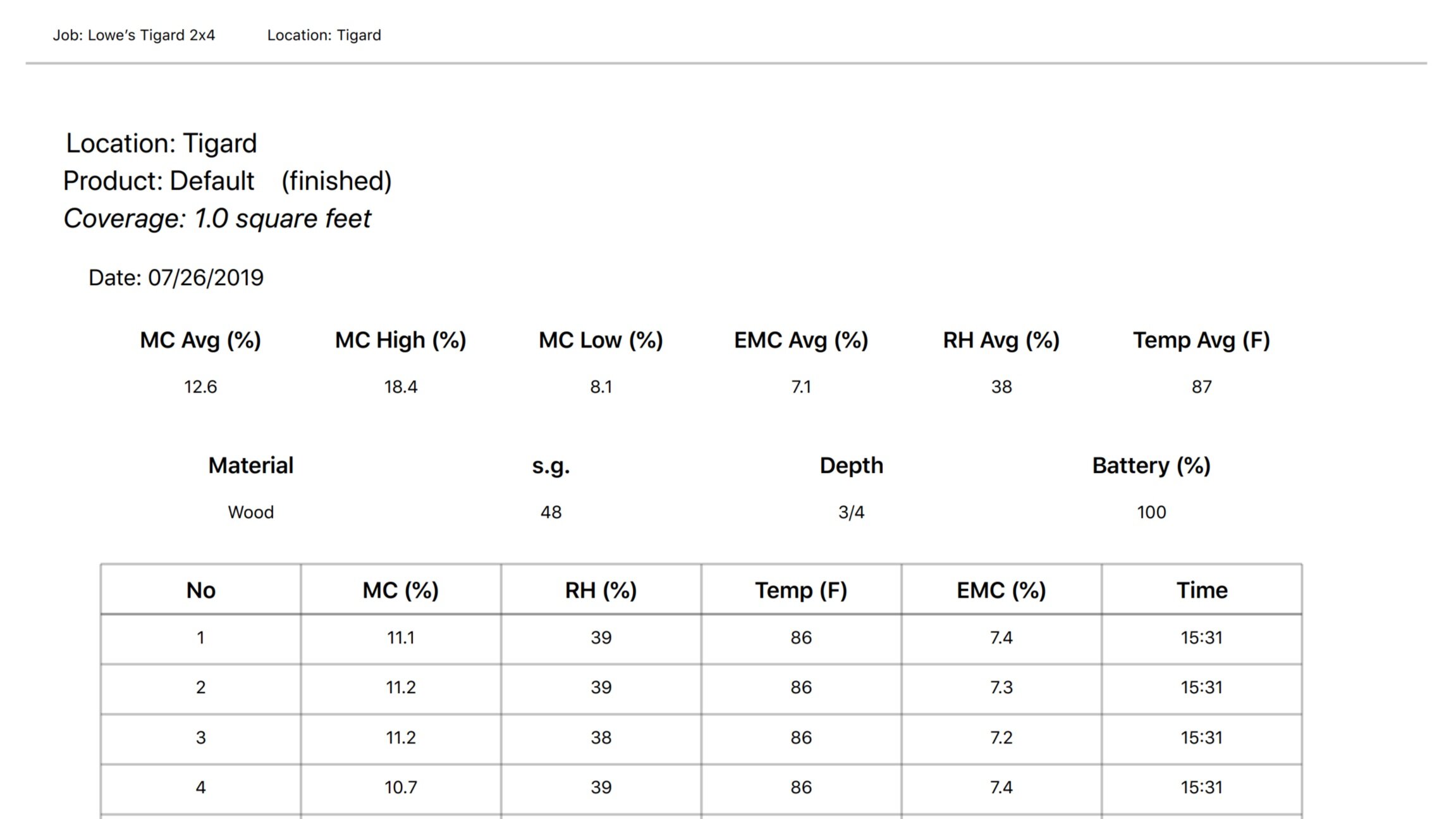

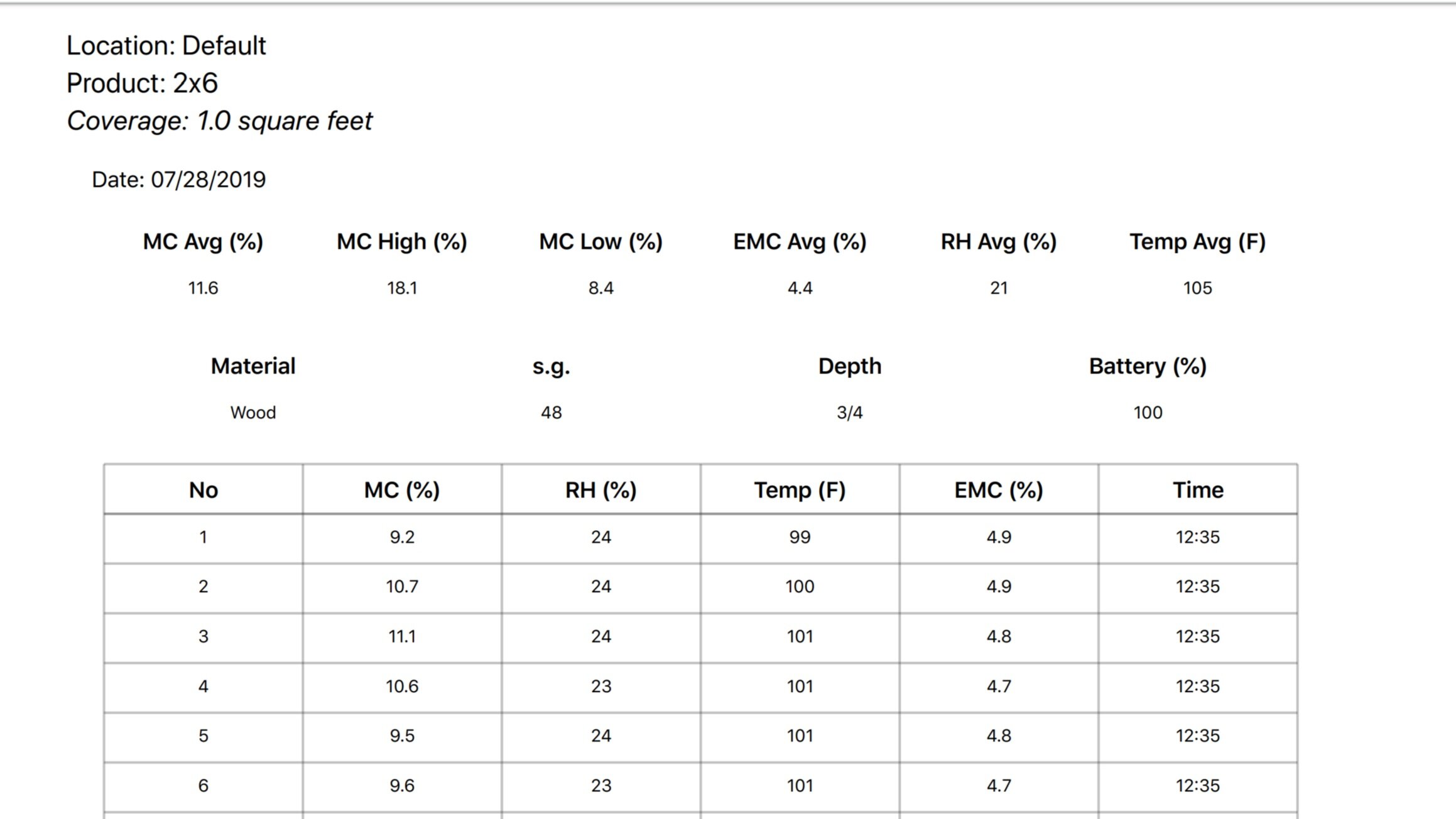

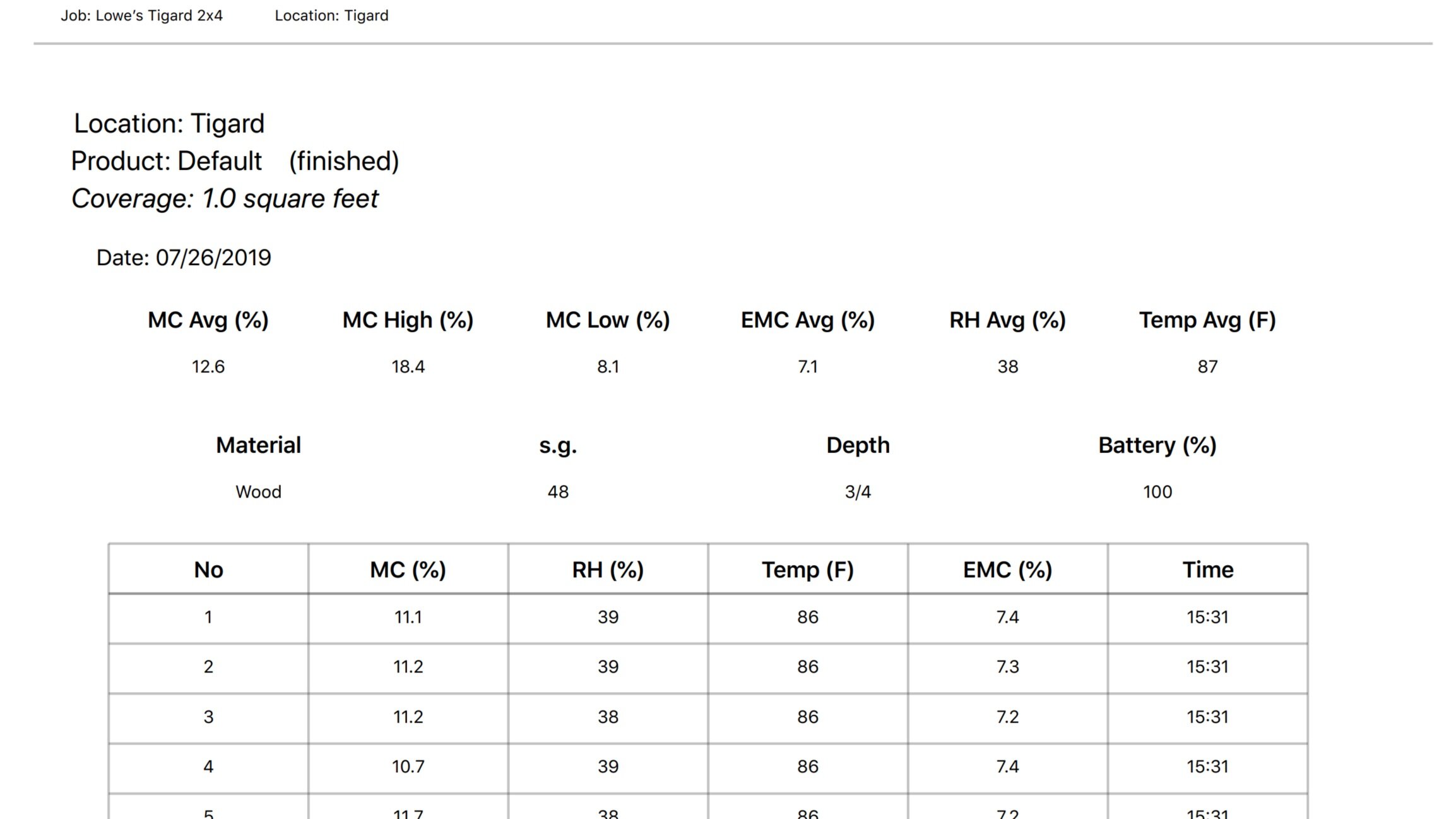

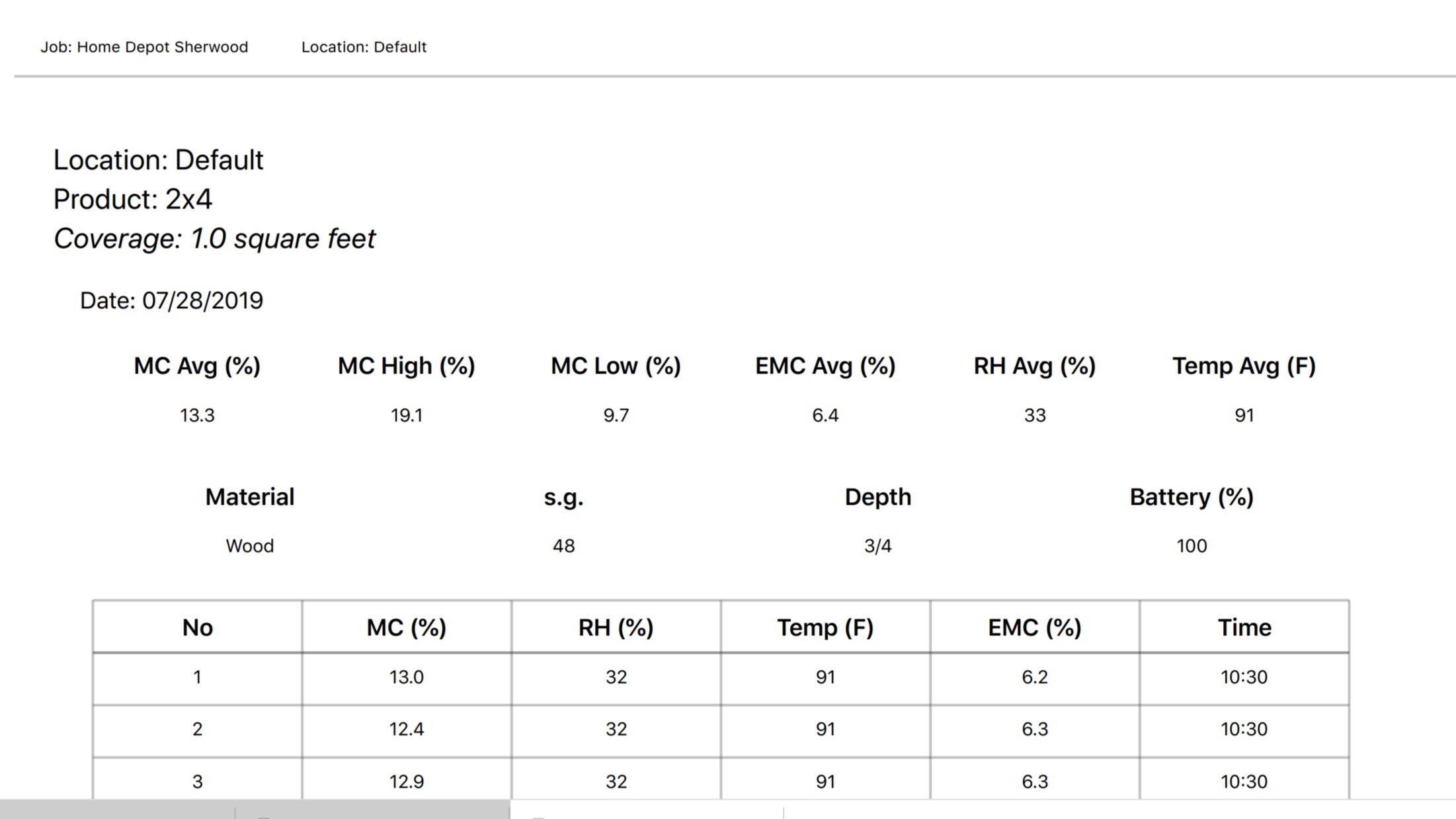

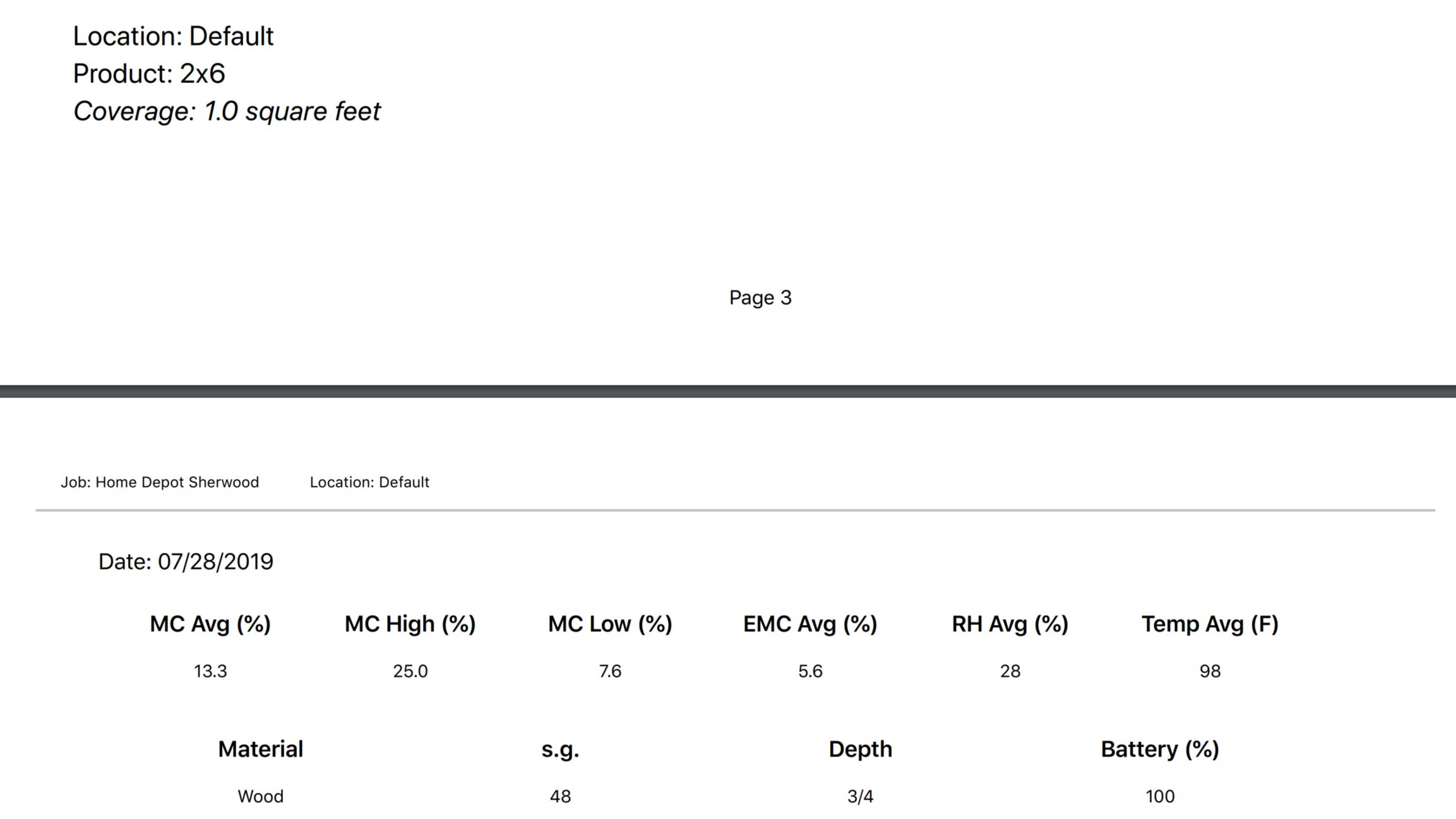

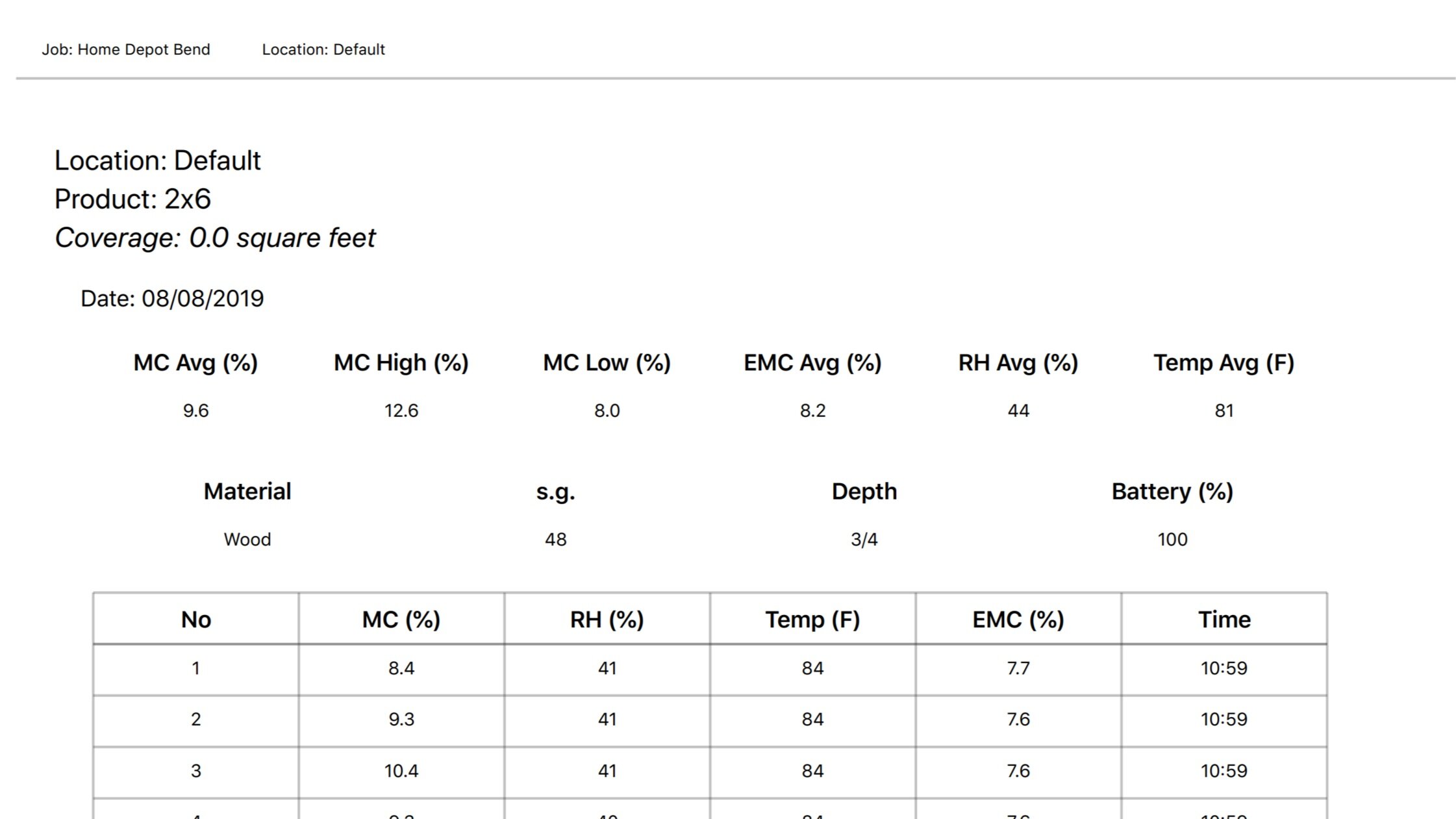

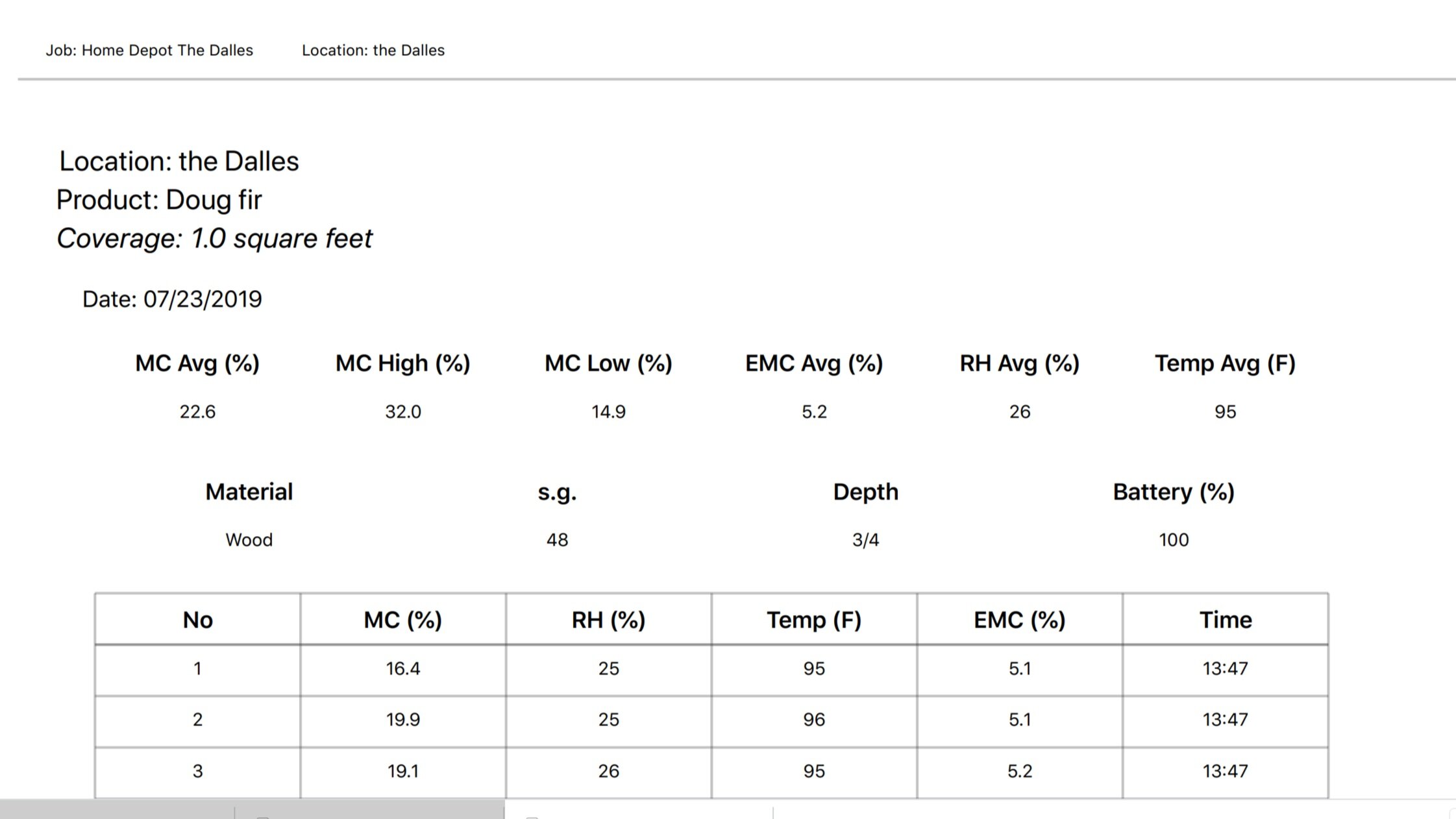

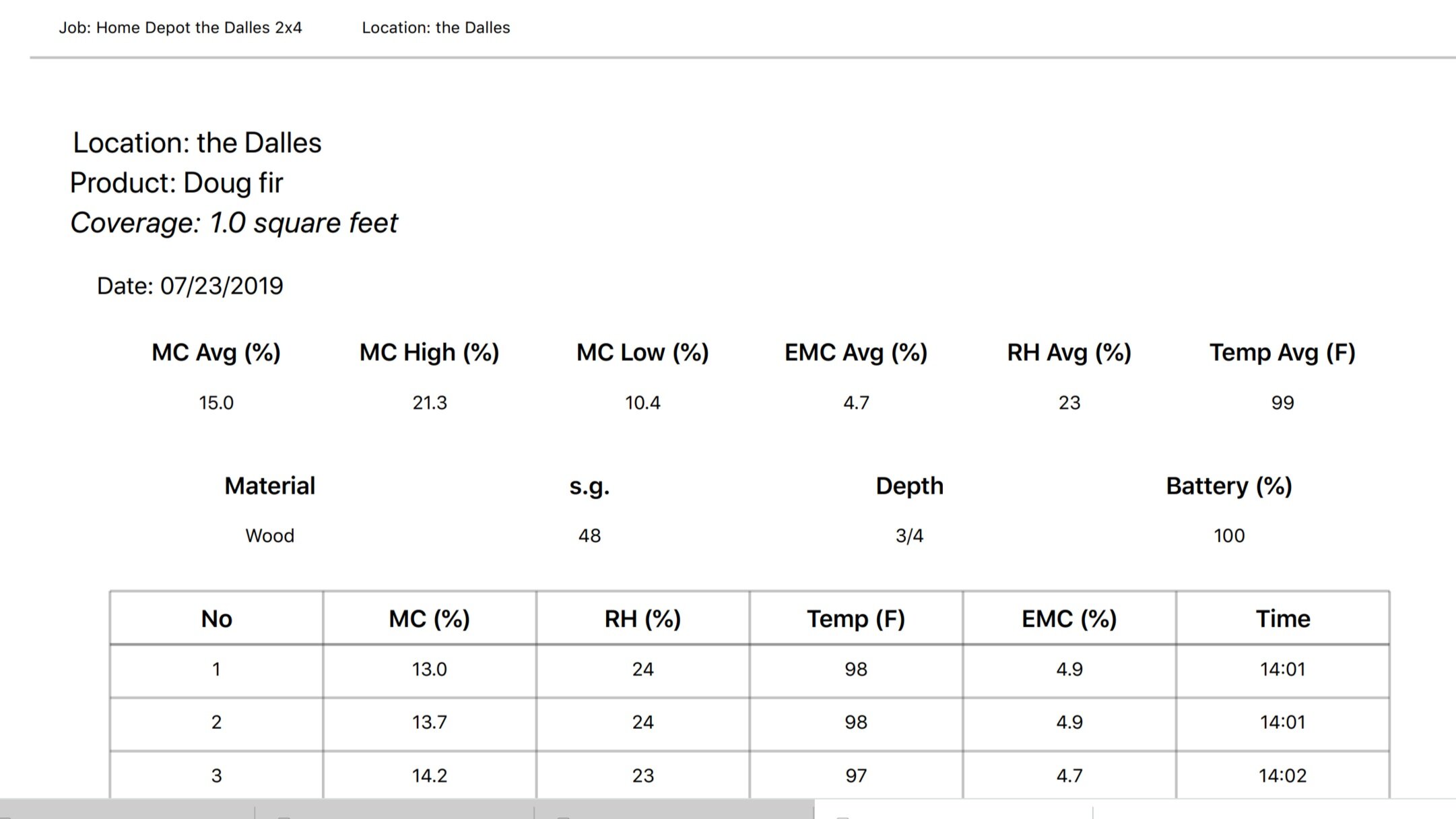

Screenshot of my data sheet taken in The Dalles, Oregon. I took 95 readings total this day.

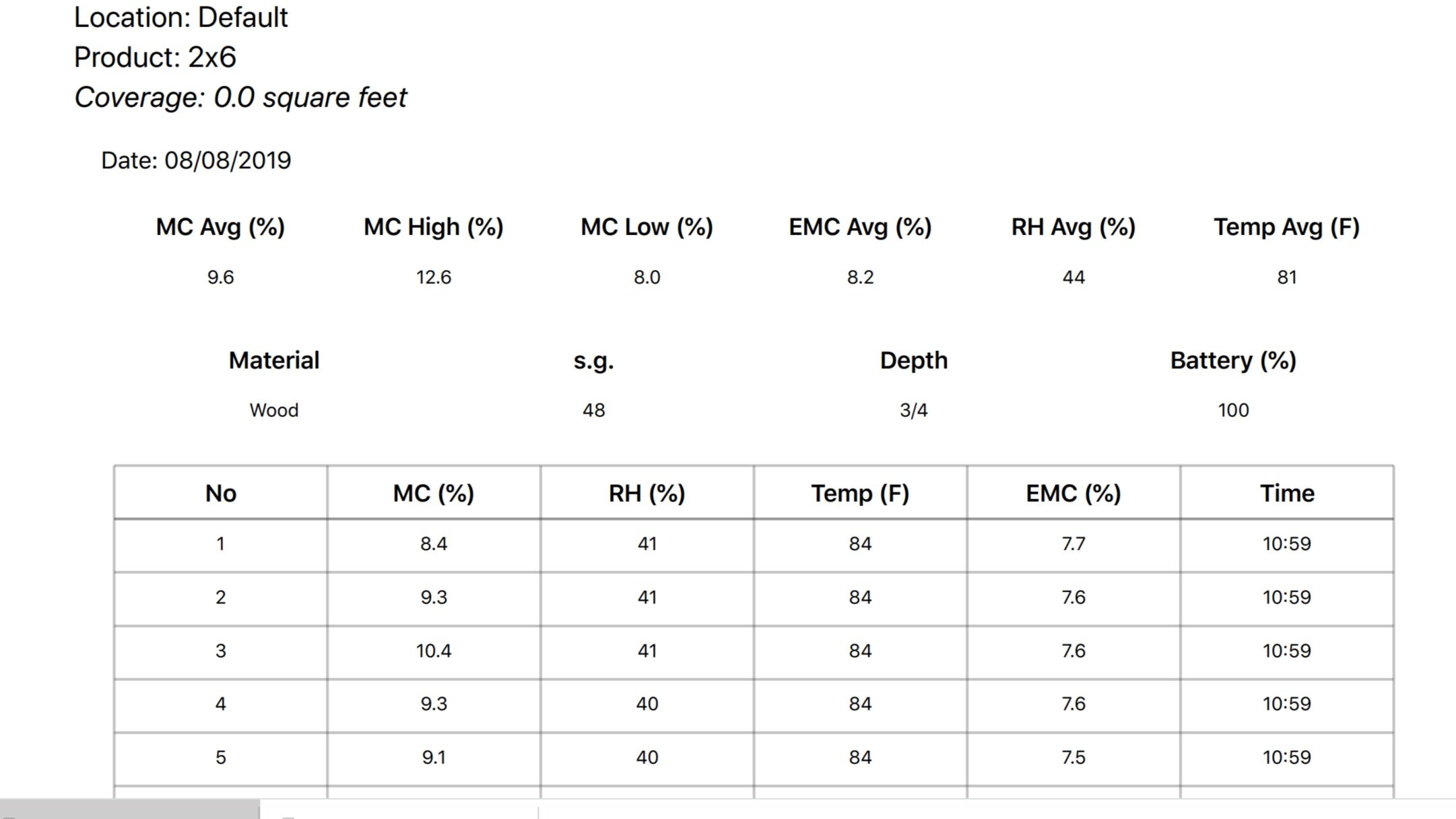

I learned about a really cool feature of the Orion series meters when taking a large number of samples, as I did in this test. Wagner actually has an app that syncs with your Orion. So you can put the meter in automatic mode and it will automatically create a PDF that includes the location, wood species and the time, temp, moisture content (MC), Equilibrium moisture content (EMC), and relative humidity (RH) of each individual sample taken. If you haven’t heard the term EMC before, don’t feel bad. It is kind of an advanced term. It basically means the MC a piece of wood should be at when totally “dried” to a given climate. Just be aware the EMC will be different outdoors than indoors. So it would be best to find the EMC of your living room vs EMC of your garage.

Wagner then does all the math for you and finds the overall average MC for all the samples. Along with the highest MC reading, the lowest MC, average RH, and average temp.

Results

Overall average for all samples at all locations 14.3%.

2x6s higher average MC than 2x4 in every location but one.

Highest average MC was at 2x6s at Home Depot in The Dalles, Oregon at 22.6%.

Lowest average MC was 2x6s at Home Depot in Bend, Oregon at 9.6%.

Most locations had a variation of at least 10% from driest board to wettest board.

Some locations had a variation of over 20% from the driest board to the wettest board.

The results were quite varied from location to location. There wasn’t even much consistency within the same town from store to store. Check out the slideshow below for some screenshots of the summary for each location. You might be surprised to see the variation from Lowes to Lowes, as well as HD to HD. The point I think is most important to focus on is that even the locations with a decently low average MC still had a variation of 10-20% from board to board. This is particularly concerning for someone wanting to make furniture. Gluing or screwing a wet board to a dry board is a sure way to get cracking and twisting.

I apologize for the inconsistent headings/titles/material names. It took a couple tries before I realized how much info I could plug into the Wagner app. I originally didn’t know I could have the location, material, and even whether it was a 2x4 or 2x6 programmed into the app.

Ok, now what? Don’t use box store lumber?

Absolutely not. I’m not here to get you to spend huge sums of money for high dollar walnut and maple. If you want to build out of 2x4s, build out of 2x4s! Your best bet is to just get it as dry as you can. So the first option is to get a moisture meter. The next option is to let the lumber sit inside for four-eight weeks to air dry. The NEXT option after that is to go a little primitive and do what I still do sometimes. That is to avoid the heavy studs. The water weight actually causes the higher MC studs to be substantially heavier. So you can kind of estimate based on weight. Another good trick is to feel the studs carefully. The wet ones will actually feel noticeably colder than the dry ones. This is due to the conductivity of water vs wood. Even if you do everything correct, don’t expect to get perfect glue lines and dead flat tables when working with stud lumber. Pick a project that will be enhanced by the inevitable imperfections of this type of lumber. DIY farmhouse style tables, shabby chic, or reclaimed styles work best with stud lumber. Another good idea is to pick a finish that will hide some flaws. Paint will hide the most, but if you want to see the wood grain, remember that the higher gloss finishes will show more flaws. A good satin wipe on finish like Osmo polyx is a great one. Along with a satin urethane like Arm R Seal. Stay away from semi-gloss and gloss finishes.

I hope you were able to get a little something from this way-to-far explanation of how dry home depot lumber is. And I salute anyone reading this far, you are a true wood geek!